How to protect your mobile phone screen made of glass? The phone case is the most important protection work, according to the author’s years of “naked” experience, tempered film for the frontal collision effect is better, but for the more common edge collision does not play a protective effect, and edge deformation extrusion is an important cause of screen edge shattering. dazzled, but now with the launch of MagSafe, the cases can be divided into two kinds according to with and without MagSafe.

Year: 2021

Producing an MFi data cable is actually not as simple as we think. After getting the MFi certification from Apple, the production starts. To produce a Lightning data cable, there are 32 processes, and it takes 45 workers on the assembly line to make it. First is the winding of the wire, the purpose is to facilitate the post-sequence pull-down operation. Set the length of the peeling outer quilt (skin), and then adjust the machine for USB A-end peeling. Then divided into shielding network copper wire, the USB end of the green and white wire wrapped around the copper wire separated and twisted into two strands of copper wire, copper wire is divided into good not to have scattered phenomenon, this step is convenient for the back of the core peeling, aluminum foil peeling, shielding wire welding.Production of an MFi cable, a total of 32 processes

What is a good iPhone cable recommendation? – Material: not easy to break II Cables Must be MFI certified III use the cable more carefully about plug in and plug off, or to put something on cable SR part to protect it.

The answer is: Due to the closed ecosystem of Apple iOS, even cell phone accessories need to be certified and supported by Apple.MFi (Made for iOS) certification is a kind of license mark that Apple authorizes the production of for accessory manufacturers.MFi is an acronym for Apple Made for iOS and is a kind of permission mark for Apple to use for the authorized production of accessory manufacturers.Apple accessories that have passed the MFi certification have certain restrictions on the quality of their components and production processes, and Apple will not provide an after-sales warranty for products damaged by using accessories that have not passed the certification. Apple data cables are used for data transfer, in addition to charging.

Generally speaking, the Thunderbolt 3, paired with a docking station, can do what any other interface can do! For example, connecting USB devices, connecting monitors, projectors, network cards, etc. In addition to these basic operations, there are a lot of very powerful features.

Goowell shows you the workshop USB cable manufacturing process. The step after wire cutting, wire stripping, connector soldering, then put on injection machine for this step. You could find that our workers work in high efficiency. Normally the connectors need to be injected 2 times, the first time is an inner moulding, the 2nd time is outer moulding. In this way, the connector is strong and not easy to break.

Torras mini 20W PD fast charging charger has rounded corners, so it doesn’t hurt to use. The input side is a cut-out design, with a fixed pin, charging more stable. The charger supports PD3.0 fast charging protocol and has two fixed voltage levels of 5V3A and 9V2.22A, which can meet the daily full-speed fast charging needs of iPhone 8 or above.

Through the assmbly process, we learned that the charger not only uses the internal U-shaped structure design, but also uses the PI highly integrated master chip SC1548C.

In terms of charging performance, the Samsung S10+ uses a USB-C interface that supports PD, QC, and AFC fast charging protocols, which is widely compatible and very selective when picking charging accessories, which is very convenient. After a full charging test, it was found that the Samsung S10+ was charging with either a PD charger or a QC or AFC charger, and its maximum power was around 15W, and it took nearly two hours to charge the whole thing. The charging power is not high inside the fast-charging phone, which is a large part of the reason or from the Note 7 incident, but the recent rumors that Samsung will follow through the system update to let S10 + support 25W fast charging, I will continue to follow up the review, welcome to continue to pay attention.

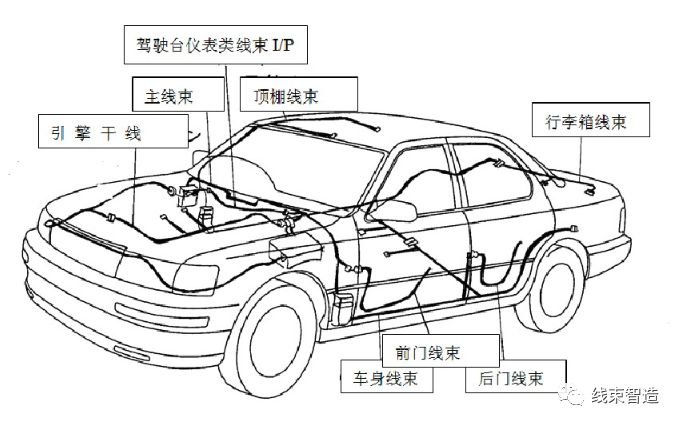

Automotive wiring harnesses play a major role in directing electric current to the electrical components in each part of the car, and in transmitting the driver’s intentions to the car and beyond.

In terms of the human body, the engine is like the heart, and the wiring harness is equivalent to the internal nervous system of the car, which is a general term for connecting all electrical components.