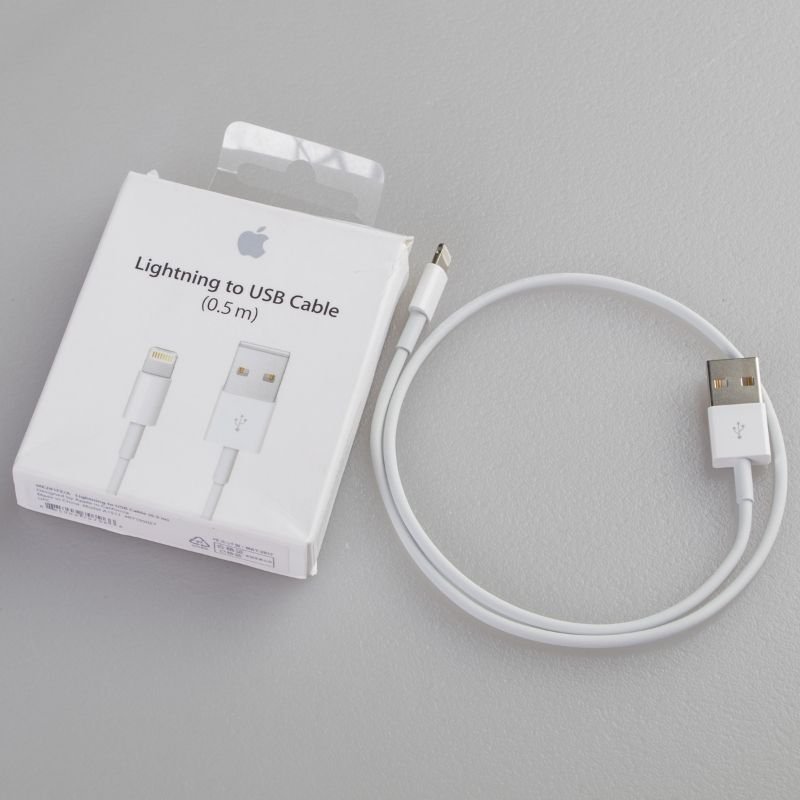

Producing an MFi data cable is actually not as simple as we think. After getting the MFi certification from Apple, the production starts. To produce a Lightning data cable, there are 32 processes, and it takes 45 workers on the assembly line to make it. First is the winding of the wire, the purpose is to facilitate the post-sequence pull-down operation. Set the length of the peeling outer quilt (skin), and then adjust the machine for USB A-end peeling. Then divided into shielding network copper wire, the USB end of the green and white wire wrapped around the copper wire separated and twisted into two strands of copper wire, copper wire is divided into good not to have scattered phenomenon, this step is convenient for the back of the core peeling, aluminum foil peeling, shielding wire welding.Production of an MFi cable, a total of 32 processes

Category: Manufacturing Process

Goowell shows you the workshop USB cable manufacturing process. The step after wire cutting, wire stripping, connector soldering, then put on injection machine for this step. You could find that our workers work in high efficiency. Normally the connectors need to be injected 2 times, the first time is an inner moulding, the 2nd time is outer moulding. In this way, the connector is strong and not easy to break.